-

-

1956 Acquisition of license to manufacture batch mills

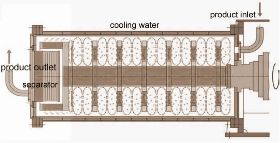

A special agitator shaft with symmetrically arranged agitator pegs and sleeves of tungsten carbide for wear protection devel- Vertical, batch operation mill for the preparation of tungsten Ideal flow behaviour due to a special agitator peg arrange-ment and the hemispherically shaped chamber floor integrated screen plate for grinding media separationIntensive cooling through a double-wall grinding tank and cooled circulation pipeline

-

-

Development of the first continuous agitator bead mill

Product inlet via rotor / immersion tube system prevents back flow of grinding media into the feed line.

-

-

Bottom up & Top down

Generally, there are two ways to obtain nano-powders. A bottom-up manufacturing method (bottom up) for chemical methods, such as chemical precipitation, sol-gel process (sol-gel),... Another method is physical method, which changes the powder particles from big to small (top down), such as mechanical ball milling,... And so on.

-

-

Horizontal Disk Grinding Machines

The Development In 1963, the first vertical agitator was developed internationally, the first horizontal agitator was developed in 1975, the first horizontal agitator bead mill with eccentric disks was introduced to the public and the horizontal disc grinder was introduced, in 2004, which became the industry standard. In the following years, the grinding media separation systems, the geometry of the grinding disks and the various grinding chamber materials were further developed.

-

-

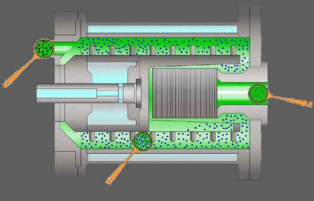

Rod-pin nano-grinding Technology

The grinding system pin nanomill shows the evolutionary develop- ment of system with the rotor-slotted pipe separating system. The enclosed horizontal agitator mill is designed for highest product throughput rates and possesses a pin grinding system for highest grinding intensity.

-

-

Ceramic comminution chamber technology

In 2011, we developed the first zirconia comminution chamber technology in China. It has no metal ion pollution and is used in batteries, pharmaceuticals, glazes, ink and food.

新材料、新技术研磨领域研究与发展工业以及学术界都需要可靠的结果。从实验室测试到规模化生产,精确的预算显得相当重要。无论是基础研究,质量控制,产品和配方的开发或流程优化,您都可以依靠我们经过充分验证的实..

新材料、新技术研磨领域研究与发展工业以及学术界都需要可靠的结果。从实验室测试到规模化生产,精确的预算显得相当重要。无论是基础研究,质量控制,产品和配方的开发或流程优化,您都可以依靠我们经过充分验证的实.. 诺研纳米砂磨机广泛应用于电池材料的研磨和分散,。 锂离子电池的正极材料主要有钴酸锂、锰酸锂、镍酸锂、三元材料、磷酸铁锂等。其中钴酸锂是目前绝大多数锂离子电池使用的正极材料...

诺研纳米砂磨机广泛应用于电池材料的研磨和分散,。 锂离子电池的正极材料主要有钴酸锂、锰酸锂、镍酸锂、三元材料、磷酸铁锂等。其中钴酸锂是目前绝大多数锂离子电池使用的正极材料... “赤橙黄绿青蓝紫”,五彩斑斓的世界需要什么,当然是颜色,她使万物呈现色彩和物质。诺瓦纳米研磨机正是这些美丽的制造者,从按照化学结构角度可以分成有机和无机着色剂两大类。而颜料和染料的定义则又和着色剂在一

“赤橙黄绿青蓝紫”,五彩斑斓的世界需要什么,当然是颜色,她使万物呈现色彩和物质。诺瓦纳米研磨机正是这些美丽的制造者,从按照化学结构角度可以分成有机和无机着色剂两大类。而颜料和染料的定义则又和着色剂在一 Visit Us:

Visit Us: