-

-

1956 Acquisition of license to manufacture batch mills

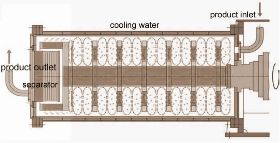

A special agitator shaft with symmetrically arranged agitator pegs and sleeves of tungsten carbide for wear protection devel- Vertical, batch operation mill for the preparation of tungsten Ideal flow behaviour due to a special agitator peg arrange-ment and the hemispherically shaped chamber floor integrated screen plate for grinding media separationIntensive cooling through a double-wall grinding tank and cooled circulation pipeline

-

-

Development of the first continuous agitator bead mill

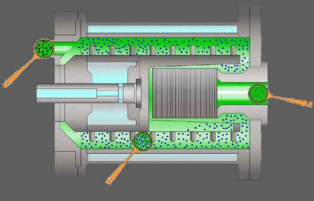

Product inlet via rotor / immersion tube system prevents back flow of grinding media into the feed line.

-

-

Bottom up & Top down

Generally, there are two ways to obtain nano-powders. A bottom-up manufacturing method (bottom up) for chemical methods, such as chemical precipitation, sol-gel process (sol-gel),... Another method is physical method, which changes the powder particles from big to small (top down), such as mechanical ball milling,... And so on.

-

-

Horizontal Disk Grinding Machines

The Development In 1963, the first vertical agitator was developed internationally, the first horizontal agitator was developed in 1975, the first horizontal agitator bead mill with eccentric disks was introduced to the public and the horizontal disc grinder was introduced, in 2004, which became the industry standard. In the following years, the grinding media separation systems, the geometry of the grinding disks and the various grinding chamber materials were further developed.

-

-

Rod-pin nano-grinding Technology

The grinding system pin nanomill shows the evolutionary develop- ment of system with the rotor-slotted pipe separating system. The enclosed horizontal agitator mill is designed for highest product throughput rates and possesses a pin grinding system for highest grinding intensity.

-

-

Ceramic comminution chamber technology

In 2011, we developed the first zirconia comminution chamber technology in China. It has no metal ion pollution and is used in batteries, pharmaceuticals, glazes, ink and food.

实验室设备主要采用标准工艺应用,容易操作,检验配方,实验新产品,将实验室数据放大到生产,验证产品放大的能力,质量和产量,及设备运行参数,实验新产品和应用

实验室设备主要采用标准工艺应用,容易操作,检验配方,实验新产品,将实验室数据放大到生产,验证产品放大的能力,质量和产量,及设备运行参数,实验新产品和应用

湿法研磨目前以机械方法的湿法研磨方式得到纳米级粉体最有效且最合乎经济效益方法。它避免了化学法的纳米粉体制造方法制造时的高成本,且产能不易放大同时和所得到粒径分布亦较大的缺陷。同时也避免了干法研磨细度难..

湿法研磨目前以机械方法的湿法研磨方式得到纳米级粉体最有效且最合乎经济效益方法。它避免了化学法的纳米粉体制造方法制造时的高成本,且产能不易放大同时和所得到粒径分布亦较大的缺陷。同时也避免了干法研磨细度难.. 机座采用卧式形式,结构采用盘片棒销混合结构,有利用加强研磨,材质采用特耐磨钢、锆陶瓷、聚氨酯等,可以应用于不同湿法研磨浆料场景,如涂料、电子浆料、色剂、油墨等,粉碎腔可以从1L至1000L不等,线性放大。..

机座采用卧式形式,结构采用盘片棒销混合结构,有利用加强研磨,材质采用特耐磨钢、锆陶瓷、聚氨酯等,可以应用于不同湿法研磨浆料场景,如涂料、电子浆料、色剂、油墨等,粉碎腔可以从1L至1000L不等,线性放大。.. 研磨腔转子结构经过重新仿真流体设计,效率提升20%,锆球减少10%,粒度分布更窄,极限细度d50小于20nm(因工艺材料而定)

研磨腔转子结构经过重新仿真流体设计,效率提升20%,锆球减少10%,粒度分布更窄,极限细度d50小于20nm(因工艺材料而定) 篮式砂磨机,传动系统采用双轴系统,区别于传动篮砂,研磨篮旋转带动篮内锆球研磨浆料,线速度更大,大大提高了研磨效率,减少了研磨死角,功率范围7.5kw至75kw不等。研磨篮定制可采用特耐磨钢、氧化锆陶瓷等材质,..

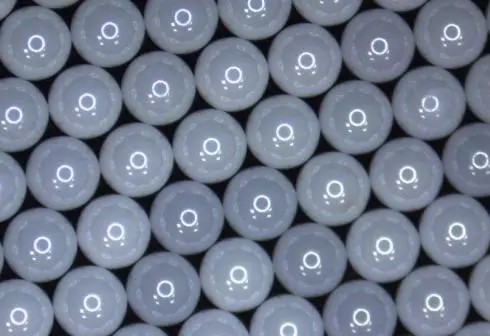

篮式砂磨机,传动系统采用双轴系统,区别于传动篮砂,研磨篮旋转带动篮内锆球研磨浆料,线速度更大,大大提高了研磨效率,减少了研磨死角,功率范围7.5kw至75kw不等。研磨篮定制可采用特耐磨钢、氧化锆陶瓷等材质,.. 原装日本进口,采用滴定法生产工艺,3Y系列氧化锆原料,更致密、耐磨,球型粒径范围0.03mm-25mm可选。提供进口COA报告。

原装日本进口,采用滴定法生产工艺,3Y系列氧化锆原料,更致密、耐磨,球型粒径范围0.03mm-25mm可选。提供进口COA报告。 采用立式结构,工程液压缸系统,更加安全、稳定,分散齿可以采用单层或双层设计,满足不同浆料粘度的需求,是粉料预混合、均匀分散的理想选择。

采用立式结构,工程液压缸系统,更加安全、稳定,分散齿可以采用单层或双层设计,满足不同浆料粘度的需求,是粉料预混合、均匀分散的理想选择。 高剪切分散乳化设备不是一般的混合设备。在批次混合工艺中,转子高速旋转所产生的高切线速度和高频机械效应带来的强劲动能,使物料在定、转子的间隙中受到强烈的机械及液力剪切、离心挤压、液层摩擦、撞击撕裂和湍流..

高剪切分散乳化设备不是一般的混合设备。在批次混合工艺中,转子高速旋转所产生的高切线速度和高频机械效应带来的强劲动能,使物料在定、转子的间隙中受到强烈的机械及液力剪切、离心挤压、液层摩擦、撞击撕裂和湍流.. 采用304或316不锈钢材质,可双层或外壁半管式冷却方式,搅拌浆可采用三叶片、框式、锚式、分散齿盘等多种形式,可包覆PU、喷涂碳化钨,罐内壁可喷PTFE、特氟龙、四氟、碳化钨等多种材质,釜可开发式、密闭式,体积0...

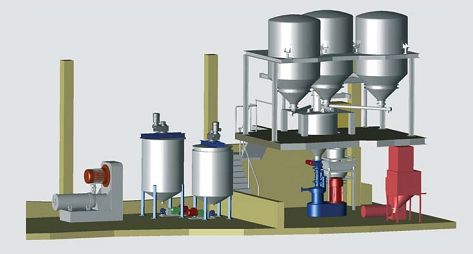

采用304或316不锈钢材质,可双层或外壁半管式冷却方式,搅拌浆可采用三叶片、框式、锚式、分散齿盘等多种形式,可包覆PU、喷涂碳化钨,罐内壁可喷PTFE、特氟龙、四氟、碳化钨等多种材质,釜可开发式、密闭式,体积0... 通过投料系统、上料系统、称重系统、浆料输送系统、过滤系统、除磁系统、预混系统、均质系统、研磨系统、储存系统、罐装系统等组成湿法研磨生产线。

通过投料系统、上料系统、称重系统、浆料输送系统、过滤系统、除磁系统、预混系统、均质系统、研磨系统、储存系统、罐装系统等组成湿法研磨生产线。

Visit Us:

Visit Us: